Emirates Global Aluminium (EGA) and Sunstone have confirmed that work on a new anode manufacturing plant in the UAE will start in 2026. The project marks the first time Sunstone, the largest independent producer of pre-baked anodes in the world, has established a manufacturing base outside of China.

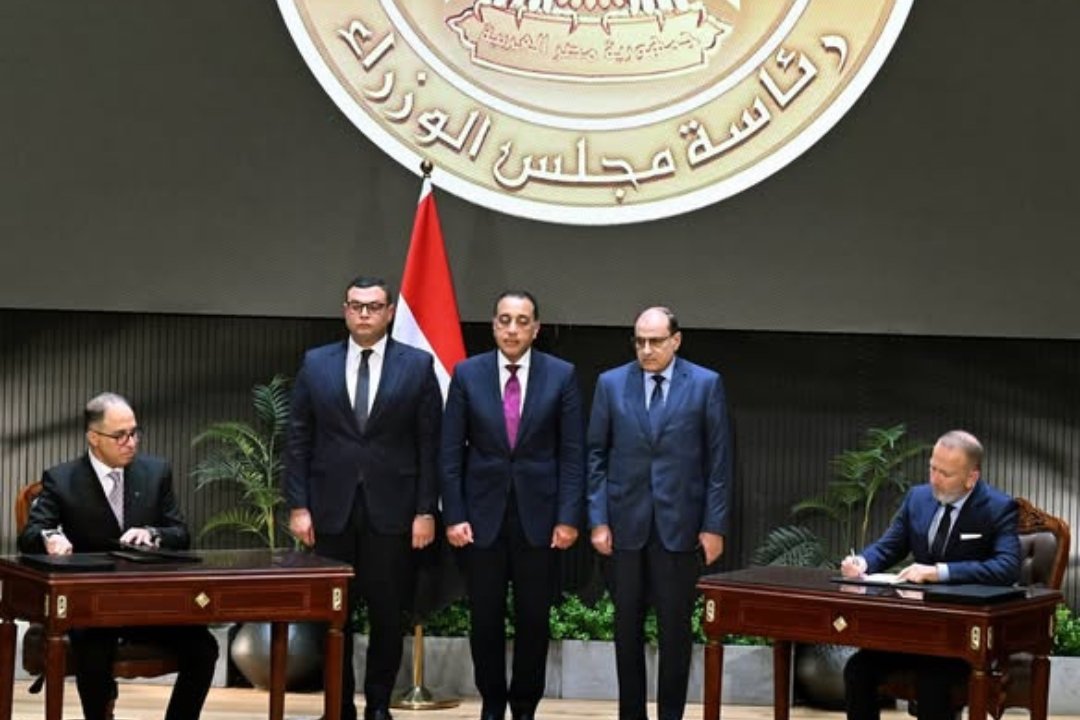

The two firms have signed a Joint Venture Agreement to deliver the facility. Sunstone will hold a 55 per cent stake in the venture, while EGA will hold the remaining 45 per cent. Both parties expect to invest a total of around $300 million into the development. Under the agreement, Sunstone will lead the construction process on behalf of the venture. EGA will act as a financial investor and the primary buyer of the finished products.

The plant will have the capacity to produce 300,000 tonnes of anodes every year. Anodes are a vital component in the aluminium smelting process. While EGA already produces 1.35 million tonnes of anodes at its Jebel Ali and Al Taweelah sites, it currently relies on imports to meet its full requirements. Once the new site is operational, which is expected by 2028, it will replace most of these imports. This shift will make the UAE one of the few nations capable of exporting anodes to the global market.

“This project creates additional export opportunities for the UAE, further increases EGA’s local procurement and our contribution to UAE economic growth, and supports EGA’s long-term security of anode supply,” said Abdulnasser Bin Kalban, Chief Executive Officer of EGA. “We are pleased to partner with Sunstone, combining our decades of anode manufacturing experience to establish their first plant outside China in the UAE. This project is Make it in the Emirates and Operation 300bn in action – leveraging UAE industrial demand to build new manufacturing in the UAE to meet local needs and expand exports.”

The initiative aligns with the UAE’s Operation 300bn industrial strategy. Lang Guanghui, Chairman of Sunstone, said: “We are honoured to establish our first overseas foothold in the UAE and partner with a benchmark enterprise like EGA, which carries half a century of industry heritage and a mission to shape the future of aluminium. This collaboration represents a substantive move by both parties to respond to the green transformation of global manufacturing. We will go all out to set new benchmarks in efficiency and lay a solid foundation for future sustainable operations.”

![[IRHM] logo](https://irhmagazine.com/wp-content/uploads/2025/08/IRHM-AWARDS-2025-1024x683.jpg)